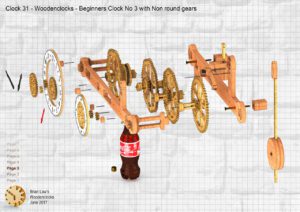

Clock 31, the third of 3 Beginners clocks, is again based on the same principles that links them all, and that is they are designed such that all the complicated cutting work is carried on the CNC router, you won’t need a lathe or Milling machine, just simple hand tools.

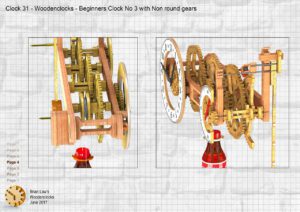

I wanted to make this one a little harder to build as it was the third in the series so it was designed with non-round gears that is a feature of a couple of the more complicated clocks available on the Woodenclocks website. This clock whilst made simpler to build using the unique snap together shafts, needs more care when it comes to the assembly of those shafts into the Back Frame as they need to be carefully lined up so the mating gears mesh together at the right point. The gears are marked with small dots to achieve this, but if you miss them out you will be in trouble.

The majority on the Clock is made from wood in both 6 mm and 12 mm thickness, along with 2 mm ground rod or drill Rod, with the clock hands and Pallets being cut from Plastic sheet.

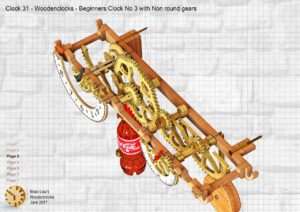

I have used a 500 ml Coke bottle for the weight as it is a convenient way of adding weight to the clock and provides an easy way of adjusting the weight by either adding or removing liquid. I had to actually add some extra weight to the bottle to make it up to 800 grams consistently. This has always been a problem with the Non-round gears as it creates a constantly changing torque.

The clock will run for about 8 hours and you should be able to get it to run within 1.0 minutes over that time, may be even better.

The design has been kept straight forward, but there is nothing to stop you adding your own touch’s to it, changing the design of the Dials can have a big impact on the clocks final appearance along with changes to the hands and the Pendulum Bob so feel free to build your own interpretation. The one things you shouldn’t change is the gears, as these have been carefully designed not only to give the correct overall ratio to the gear chain, but more importantly to ensure meshing of the constantly changing profiles.

Another feature of the Beginners clocks is the simple winding arrangement, with a single cord wrapped one and a half times around the drum, I used Ø2 mm Paracord

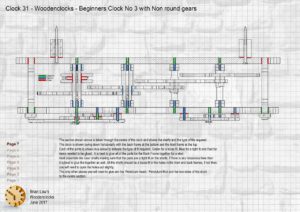

If you want to cut out parts on a scroll saw you can use the the PDF file included with the purchased downloads to do this. This PDF is one big sheet of all the parts so you will need to follow the PDF printing instructions below.

DXF files, and the IGS and STP files that can be used with your CNC machine can be downloaded here for $26. You also get the unrestricted version of the PDF files that can be printed at full size.

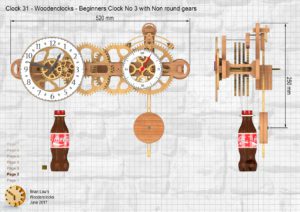

Drawings for this clock in PDF format can be downloaded here. These free files are low resolution and not to scale and only a sample of the full set that comes in the paid for version. Clicking here will download the PDF file directly to your browser, may take a few moments so please be patient.

Details of the materials and equipment needed to build this clock, along with Hints and Tips.

Instructions for assembling the clock components.

A sample from the DXF file – the file is purposely low resolution, with no vector data.The actual files purchased above are included on one large sheet so that they may be directly loaded into your CAM program.

To print only a single item of the drawing to scale using Adobe Acrobat Reader, do the following:

Go to Edit, then click on Take a snapshot, move the cursor to the top left of the item you want to print and hold down the left mouse button whilst you drag a box around the item. The inside of the box turns blue and you can now go to File and then click on Print. This brings up the print dialogue, make sure Selected graphic is selected and that the Page scaling is set to None and the click on OK. As long as your printer is connected you will have printed the item at size. Do this for each item you want to cut out.