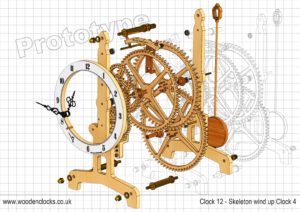

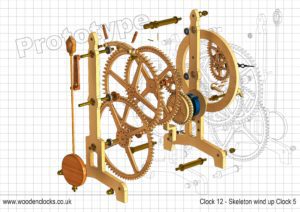

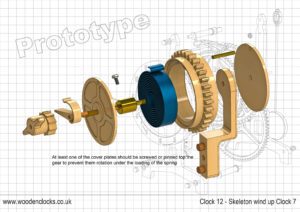

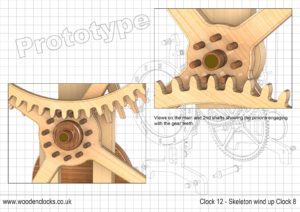

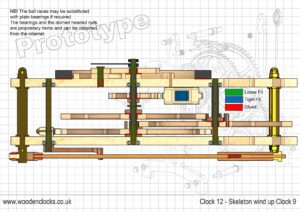

This clock is a departure from the normal design concept used in the previous clocks as it introduces a mainspring clock drive instead of the normal weight driven design. It was introduced here along with the shorter pendulum to allow the clock to sit directly onto a table or shelf. A further departure is the use of a 60 tooth escapement wheel which allows me to use the simple gear train first used in Clock 11.The mainspring is housed in a special gear mounted in the 7 o’clock position, it drives the main shaft through an intermediate gear at the front of the main shaft. The winder is mounted to this mainspring gear and a Ratchet and Pawl arrangement fitted to maintain the tension in the spring. To ensure the minimum of friction in the design Ball races are fitted to all the shaft pivots and a lightweight pendulum has been introduced to reduce impulse load necessary to keep the clock working to the minimum.

The clock is small, designed to fit onto the smaller CNC machines and measures 350 mm (14 inches) tall and 190 mm (7.5 inches) wide.

The clock will run for 15 hours on a single wind up.

I have introduced some instruction sheets to help with the assembly of this clock with the hope it will help the builder to more readily understand the construction and working of the clock.

A prototype was built to iron out all the little problems that could arise with this new design approach using a clock spring to drive it instead of an weight you can see that I used a lot of different materials in the prototype to find out what worked best and although the plastic gears and escapement were easier to construct from sheet plastic, the finished result did not really look as good, so they are still shown as wood on all the rendered images.

I did keep the brass parts as they seem to complement the wood really well, and the carbon fibre tube for the Pendulum Bob works really well so I kept that in the design as well.

If you would like to purchase the DXF or DWG files for CNC machining and the full unrestricted Drawings in PDF format for use with a scroll saw then go to the BUY NOW button below.

The spring I used in this clock is available from Cousin UK.

DXF, DWG 2D files, and the IGS and STP files that can be used with your CNC machine can be downloaded here for $26. You also get the unrestricted version of the PDF files that can be printed at full size.

Special offer you can get all of the 2D files of Clock 12 plus those for Clock 14,16 and Clock 17 as well for only $36.

To view the assembly instructions for the clock click here, these include illustrated instructions to assemble the clock along with details of materials and equipment needed to construct the clock.

Drawings for this clock in PDF format can be downloaded here. These free files are restricted so that you can only view them on screen but not print them. Clicking here will download the PDF file directly to your browser, may take a few moments so please be patient.

To print only a single item of the drawing to scale using Adobe Acrobat Reader, do the following:

Go to Edit, then click on Take a snapshot, move the cursor to the top left of the item you want to print and hold down the left mouse button whilst you drag a box around the item. The inside of the box turns blue and you can now go to File and then click on Print. This brings up the print dialogue, make sure Selected graphic is selected and that the Page scaling is set to None and the click on OK. As long as your printer is connected you will have printed the item at size. Do this for each item you want to cut out.