Welcome to Brian Law’s Wooden Clocks

Over the last 30 years I have been designing and building wooden clocks and the one thing that they all have in common is they are entirely mechanical with no electrical or electronic drive systems, they either use a weight or a powerful spring to drive them. That is going to change on this next clock with the introduction of a Pendulum Drive Unit usually used along with a quartz powered motor to drive the hands of a clock.

This has been a most rewarding project, the clock running for weeks on end without rewinding and to within a minute a day. I have always shied away from any non-mechanical Drive mechanism for the clocks as I always thought of it as cheating a little, but this one has a purely mechanical gear train and escapement and the inclusion of an inexpensive Pendulum Drive Unit that requires no knowledge of electronics to incorporate. Most satisfying, and I hope you feel the same if you choose try it for yourself.

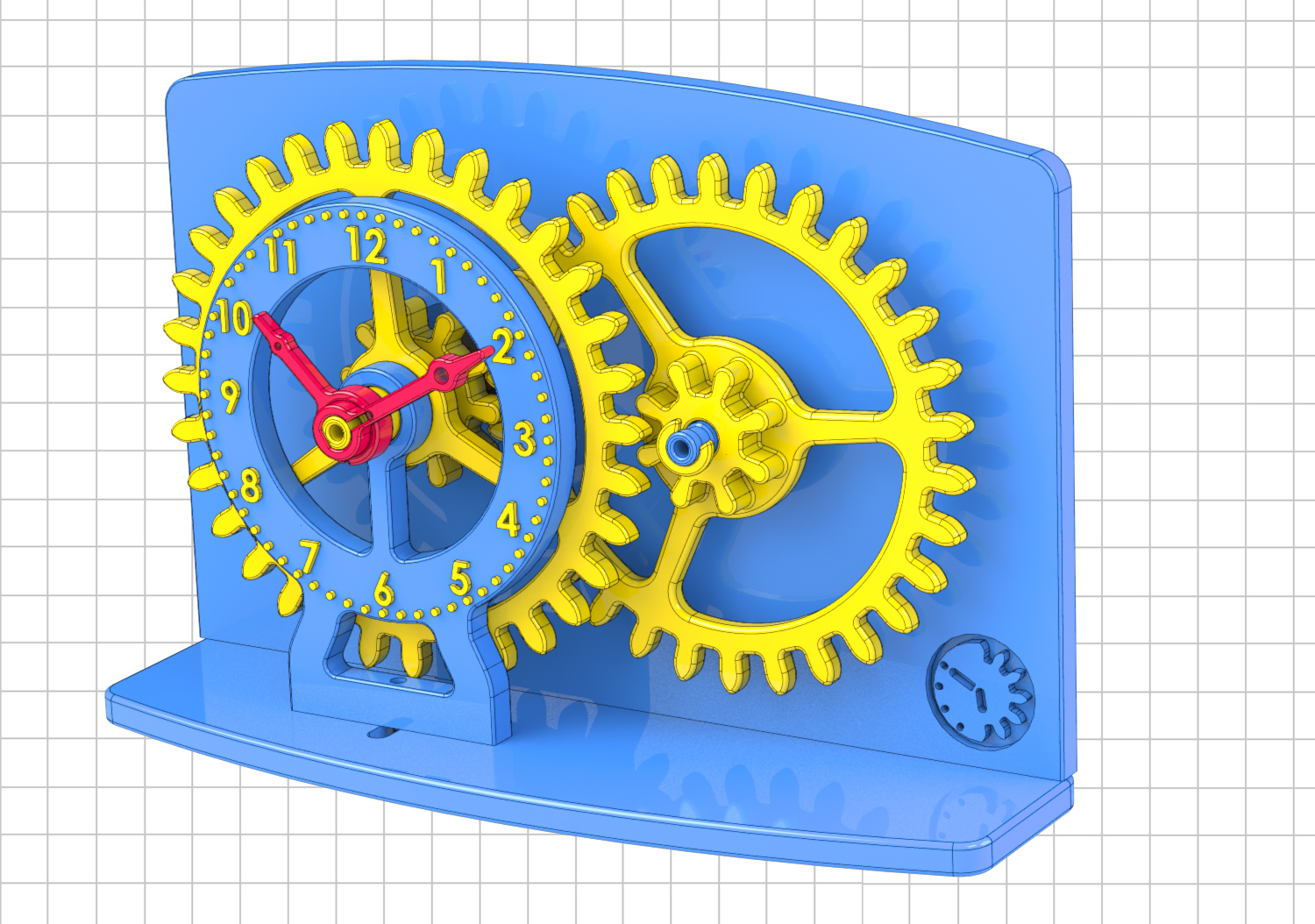

The Pocket watch clock is based on an earlier design (Clock 9), which used a spring to drive the mechanism and was designed to be made from wood. This clock, on the other hand, is smaller and designed to be built using 3D printing and is driven by a Quartz motor, which simplifies the design by reducing the number of parts needed and, as a bonus, makes the clock more accurate. It also enables the clock to run continuously for several months.

By using a Quartz drive, the whole clock is simpler to make, so it is ideal if you have limited time available to dedicate to the project.

The STL files supplied for the 3D printer include 2 dials, one with normal numbers and the second with Roman numerals. If you are not able to change the filament to a second colour to print the numerals, then the detail drawings provided include scale versions of the two dials for printing and sticking on.

Clock 62 is a simplified version of Clock 60, designed to be

made entirely on a 3D printer. It still requires the inclusion of a Quartz

drive unit, which can be obtained from many places on the internet. This

simplified version has the advantage of being a lot less expensive at $8.

With so many clocks now, it is difficult to decide where to start looking for your next project, so I have split them into the three categories shown below, just click in the group you want to look at first to go to the visual index for that group.

I have designed this clock for my young great grandson, with a Knights and Castle theme. I have revisited the Spring powered clocks once again to allow the clock to be placed on a cabinet or shelf with none of the hanging parts that young fingers can grab and pull on.

I have put together a chart that tries to list all the relevant information about each clock so as to make your choice a little easier. The chart is actually a PDF file…

This question is looked at in detail in the Woodenclocks Blog. The article focus’s on the tools and equipment needed from the minimum, on to the requirements of a well equipped workshop.

How to Design and Build a Wooden Clock

If you are looking for a challenging woodwork project that is going to test your skills and imagination then building a fully working wooden clock is just what you need. This Kindle book will help you to design your own clock with the included sections on the design and calculation of gear trains along with guidance on gear tooth design. It will also introduce you to some of the many escapement designs used in clocks through the centuries to control and maintain the accurate movement of the clocks mechanism. There is guidance for cutting out parts by hand or by CNC machine or even by 3D printing. To get your copy follow the link below to get your copy.

The files for the clocks are not included, these are paid for separately.

Woodenclocks Journal

Over the last 20 years I have designed and built prototypes of more than 40 different wooden clocks. In the main I have enjoyed the process and think it is now time to look at this body of work as a whole, so this E-book takes the form of a journal and is available as electronic file in PDF format. The book contains nearly 200 pages of illustrations of the 42 clocks so is an excellent fund knowledge on wooden clocks.

Each clock has its own set of pages with a short precis of its attributes and a description of its unique features and at the end of the book there are 6 pages showing the clocks hanging in line so that you can get a sense of their relative sizes.

Links to the clock’s website page are accessed through the blue outlined boxes on the first page of each clock so you can obtain further information and detail drawings for the clock concerned.

Woodenclocks Journal

It is a large file and will take some time to load so patience is required when downloading.

A design journal for Wooden clocks, with occasional thoughts on side issues related to clock design, materials, mechanisms and automata in general. There are articles on choosing the right materials along with those concerned with the equipment you will need to build your own clock.

To browse the Blog click here >

If you are not sure about making the wooden gears for the clock you can download the samples shown here to give it a try. Whether you will be cutting it out by hand or by CNC machine these free files will help you to decide.

BUNDLE 1 – Clocks 6, 9 and 10 are probably the most challenging to build.

BUNDLE 2 – Clocks 3 and 7 are all built from the bottom up in inches.

BUNDLE 3 – Clocks 12, 14, 16 and 17 are all of the wind up clocks driven by a spring.

BUNDLE 4 – Clocks 1, 2, 4 and 5 all of the original clocks.

BUNDLE 5 – Clock 15 + Gears for Projects + Mechanisms DXF and PDF Drawing files

BUNDLE 6 – Starter Clocks – Inches – Files for Clock 41 and Clock 47 *

BUNDLE 7 – Starter Clocks – Metric – Files for Clock 39 and Clock 45 **

The Beginners Clocks – Files for Clocks 30 and 31

The inch ones – Files for Clocks 24 and 25

Easy and Hard – Files for Clocks 21 and 33

Each bundle contains the Drawings as a PDF file and the DXF files for machining and they cost $36.

* Bundle 6 includes a book and costs $42

** Bundle 7 includes a book and costs $42

If you require the DXF files for any of the clocks on the site then go to the page for the clock that you require, where you will find the DXF files listed along with model files for the newer clocks. The files can be used to produce Gcode so that you can machine the profiles on CNC machine.